A PROTOTYPE of S.M.A.R.T.

Transport

Switchable: offline to local loops and to docking

stations means delivery to more destinations

Modular: Built off site in 50 foot elevated sections and carries a

mix of different vehicles

Automated: start up, speed, reporting, merging, switching,

docking , loading and stopping

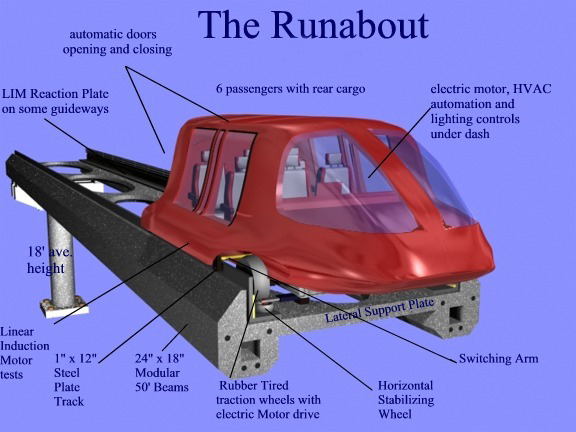

Robotic: doors, loading, locking, lighting, propulsion, HVAC,

security and communications

Telematic: Interactive media in every seat that informs about the

stations on the route and links to Internet

OUR

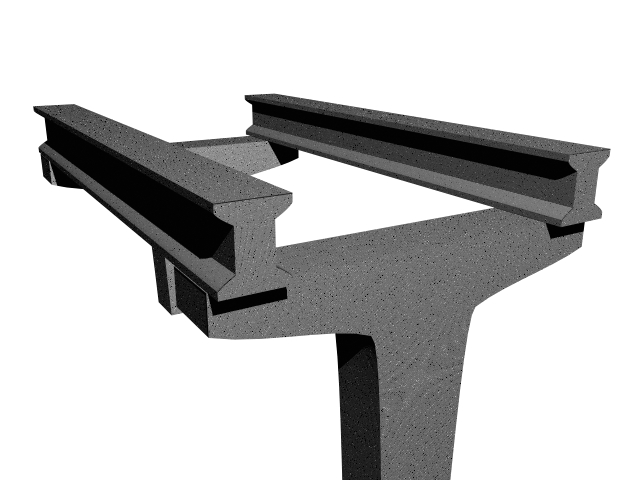

DUAL BEAM GUIDEWAY ILLUSTRATED IN DENVER

The Denver Tech Center and Greenwood Village serve as a 5 mile

local loop model over a background of 50 million square feet of commercial uses and office

space supporting a daily population of 75,000 people. This area is currently

served with local circulator bus system, now free, provided by a group called the

Southeast Transportation Authority: (SETA)

THE TECHNOLOGY

COMPONENTS

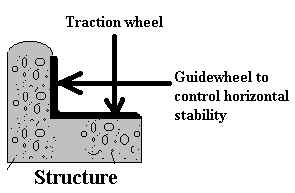

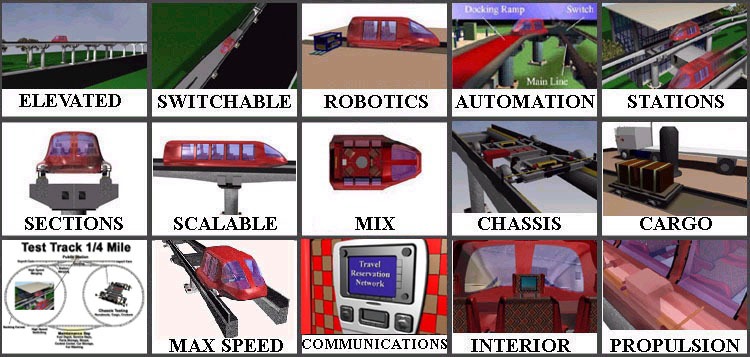

The following matrix illustrates the component

pieces of our automated GUIDEWAY configuration.. It can be built first in a low speed

local loop configuration from $7.5 million per single lane mile and

later as a high speed line-haul configuration that we believe can be built for about $10

million per double lane mile. These conceptual illustrations show how our concepts

would look and operate. They have not been engineered yet, and may change with new

information. When the prototype engineering is available, it will be considered trade

secrets and will not be available to the public on the Internet. The Initial Research

Agenda will focus on combining beams with controls, switching and propulsion. The concepts

we are proposing, uses "interoperability" meaning it can transfer from a line

haul to a local loop for that critical last mile delivery that brings convenience to the

Ridership. In fact the nature of the guideway may evolve over the years and still maintain

this flexibility with new designs so long as there remains the critical topology shown in

this graphic:

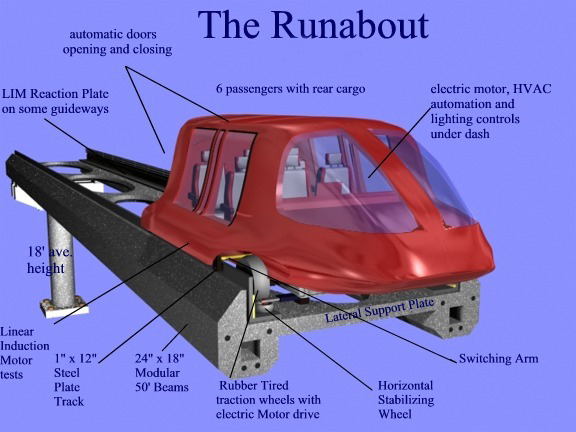

Using this simple rubber tire concept to

control the vehicle, the guideway can take many forms which include space frame see

thru, solid, flat plate or dual beams as we show below. It could even be on the ground

like a curb and gutter pan (shown above) where feasible. It's propulsion power could come

from the guideway as we propose or it could be battery or fuel cell propulsion. The

automation controls would need to be standard. The icons below describe the components to

this system.

See Specifications

CLICK ON EACH ICON TO VIEW INTERACTIVE IMAGES OF ITS FEATURES. These are animations that require approximately ten minutes to download at 56Kbps or only seconds with a high bandwidth connection.

OPERATING POLICIES

THE

CERTIFICATION ISSUE

VIEW FROM GROUND AS MOST PEOPLE WILL SEE IT This concept illustrates the least visual intrusion from the smallest mass up in the air and the openness between the beams offers a very small area for snow and ice to accumulate. Smallest mass means least cost - estimated at one half of light rail.

LINE HAUL CONFIGURATION

- INTERSTATE HIGHWAYS

This is where automation can make a big difference by

carrying higher ridership(15 seats) much further distance more than local loops.

Once it is built, the majority of the farebox revenue can go to the bottom line

because of automation. The following animations show how such a system can be automated.

These designs are to illustrate concepts and are not yet engineered.

| A SKYWAY BREAKTHROUGH What is needed is an elevated GUIDEWAY that provides most of the functionality rather than being provided by the vehicle. Our GUIDEWAY will combine all these functions 1. Elevated for

non stop 2. The Automation Controls Automation requires a dedicated, exclusive, elevated Guideway. Any system at grade, will get caught up in the same traffic congestion it is trying to solve

|

|